Prefabrication of structural, tube and merchant sections products

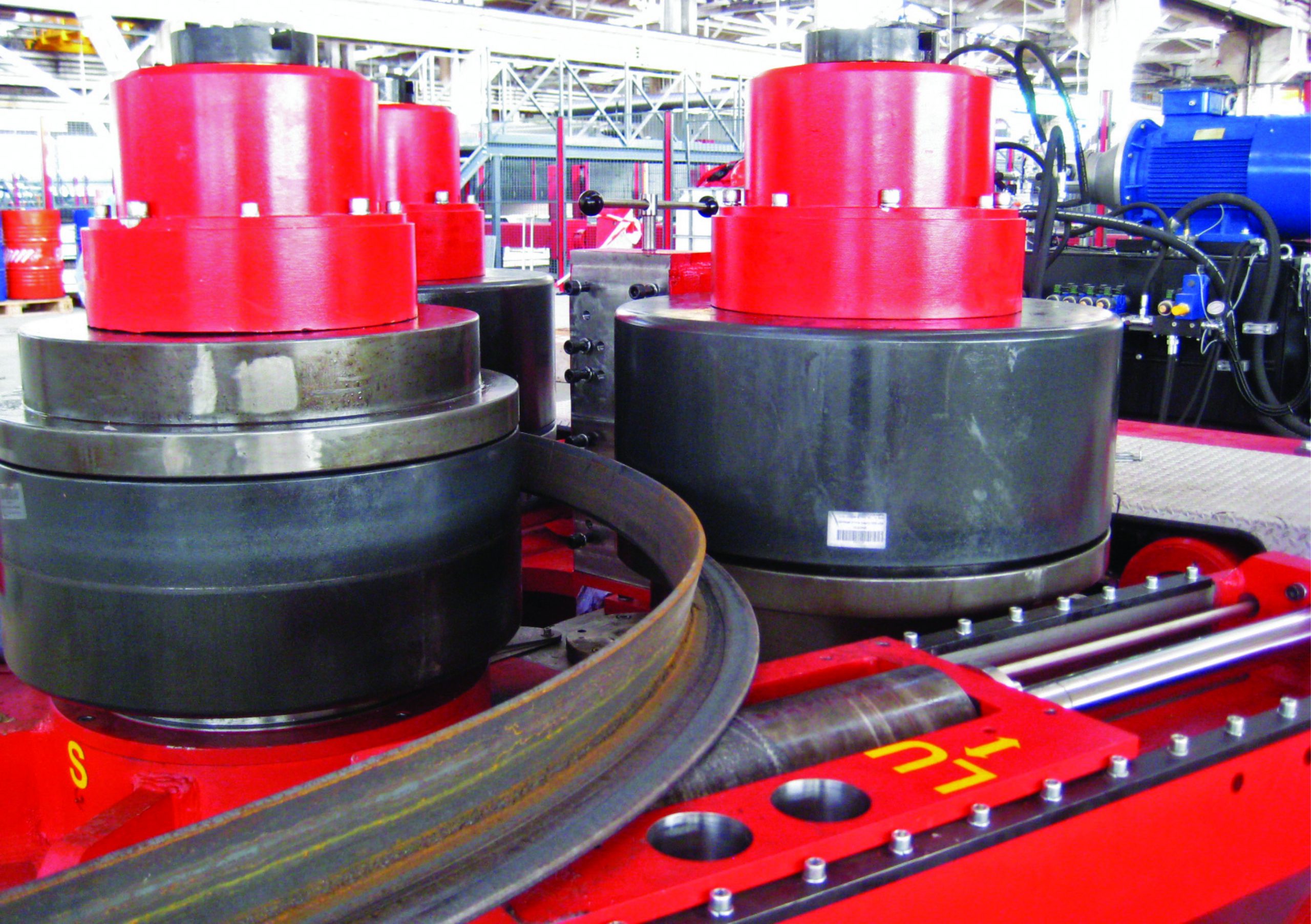

Profile bending

| Flat bar edgewise | 250 х 70, Ø 1800 mm |

| Flat bar flatwise | 500 х 80, Ø 1800 mm |

| Square bar | 170, Ø 2200 mm |

| Round bar | 200, Ø 2200 mm |

| Angle with leg outwards | 200 х 28, Ø 1600 mm |

| Angle with leg inwards | 200 х 28, Ø 1800 mm |

| T-bar with leg outwards | 200 х 28, Ø 1600 mm |

| T-bar with leg inwards | 200 х 28, Ø 2500 mm |

| T-bar with leg upwards | 200 х 28, Ø 1600 mm |

| Rectangular tube | 250 х 125 х 12 mm |

| Square tube | 225 х 12 mm |

| UPN channel with legs outwards | UPN 550, Ø 2200 mm |

| UPN channel with legs inwards | UPN 550, Ø 3000 mm |

| IPN-beam with legs in parallel to horizontal plane | IPE 600, Ø 2200 mm |

| HEA -beam with legs in parallel to horizontal plane | HEA 450, Ø 3500 mm |

| UPN channel with legs flatwise | UPN 300, Ø 20000 mm |

| IPN-beam with legs in perpendicular to horizontal plane | IPE 360, Ø 20000 mm |

| H-beam with legs in perpendicular to horizontal plane | HEA 300 Ø, 20000 mm HEB 260, Ø 12000 mm |

Profile horizontal bending

| Press power | 400 t |

| Adjustable travel | 50 – 1050 mm |

| Operating height | 850 mm |

| Max width | 1050 mm |

| Max. length of bending operating area | 8000 mm |

| Max. profile | HEM 1000 |

| Max. part weight | 9000 kg |

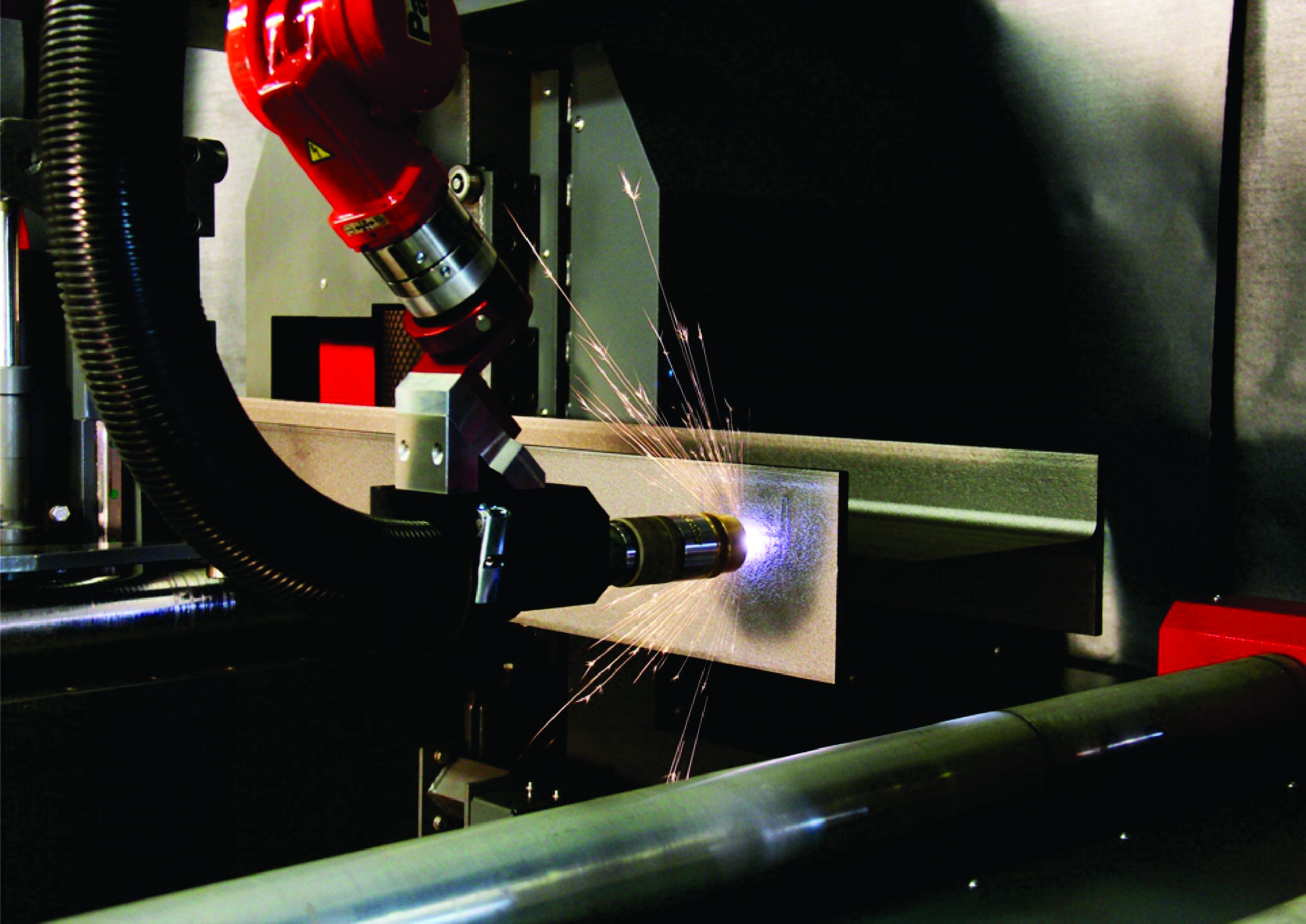

Sections processing on machining robot

| Min/max thickness | 10 – 600 mm |

| Min/max. width | 60 – 1250 mm |

| Min./max. length | 45 – 18000 mm |

| Maximum load per 1 running meter | 1100 kg/m |

| Max. part weight | 9000 kg |

| Cutting | oxyfuel gas or plasma |

| Plasma source | HPR260XD |

| Plasma cutting | 3 – sided |

| Processing types | orifices, sections and bevels |

Round pipe processing on machining robot

| Min./max. diameter | 60 – 1150 mm |

| Max. length | 16000 mm |

| Maximum load per 1 running meter | 1100 kg/m |

| Max. part weight | 8000 kg |

| Cutting | oxyfuel gas or plasma |

| Plasma source | Fine Focus 800 |

| Processing types | orifices, sections and bevels |

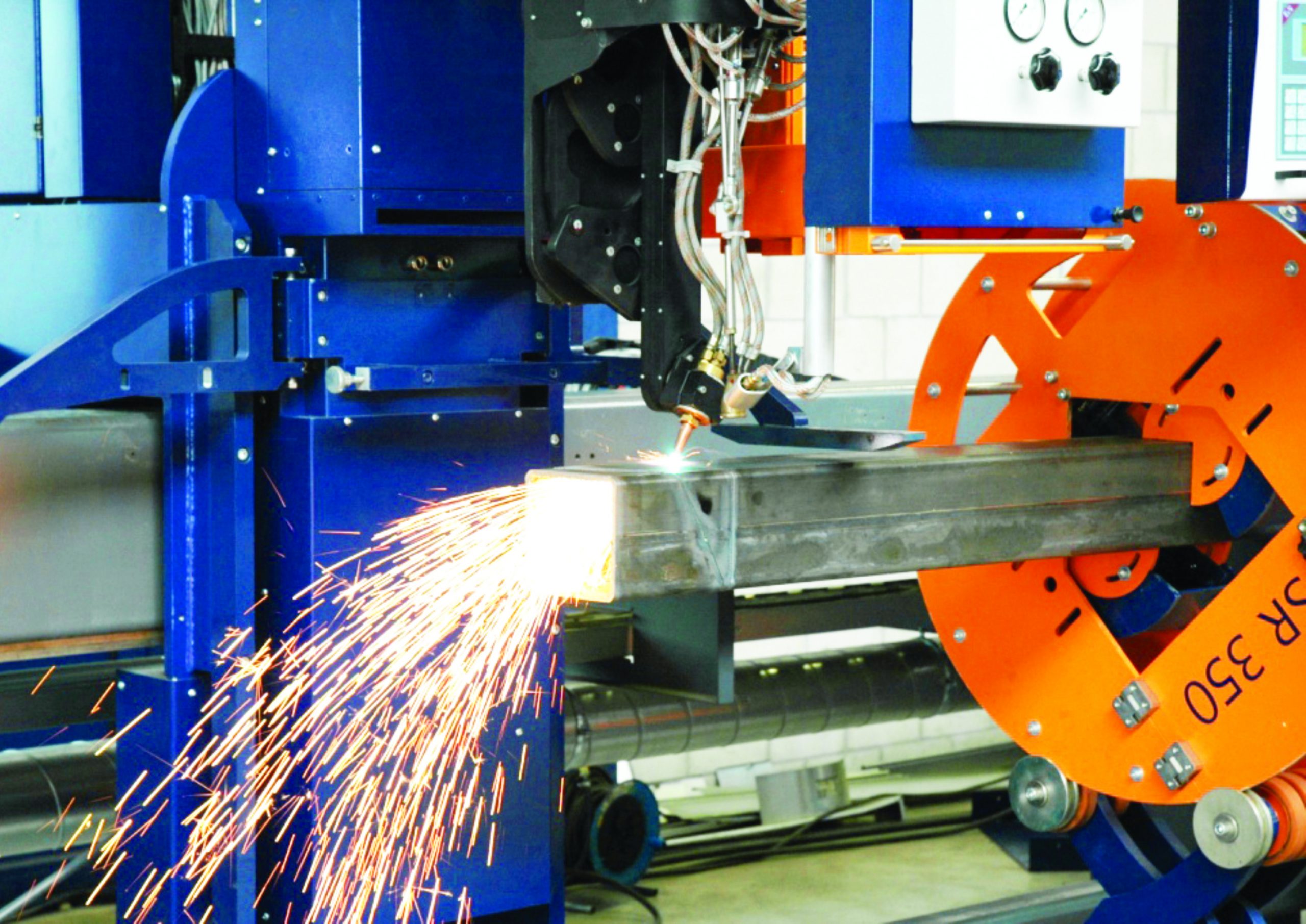

Hollow sections processing on machining robot

| Min./max. square size | 60 x 60 – 350 x 350 mm |

| Min./max. rectangular size | 60 х 120 – max 350, ratio 1:3 mm |

| Max. length | 16000 kg/m |

| Maximum load per 1 running meter | 1100 kg/m |

| Max. part weight | 2500 kg |

| Cutting | oxyfuel gas or plasma |

| Plasma source | Fine Focus 800 |

| Processing types | orifices, sections and bevels |

Profile cutting to size

| Min/max thickness | 10 – 500 mm |

| Min/max. workpiece width when cutting at 0 | 50 – 1130 mm |

| Min/max. workpiece width when cutting at an angle of 15 degrees | 50 – 1060 mm |

| Min/max. workpiece width when cutting at an angle of 30 degrees | 50 – 925 mm |

| Min/max. workpiece width when cutting at an angle of 45 degrees | 50 – 725 mm |

| Min/max. workpiece width when cutting at an angle of 60 degrees | 50 – 470 mm |

| Min./max. length | 45 – 18000 mm |

| Maximum load per 1 running meter | 400 kg/m |

| Max. part weight | 9000 kg |

Drilling of orifices in profiles

| Min./max. height | 10 – 450 mm |

| Min/max. width | 60 – 1050 mm |

| Min./max. length | 45 – 18000 mm |

| Maximum load per 1 running meter | 400 kg/m |

| Max. part weight | 9000 kg |

| Orifice diameter | 8 x 40 mm |

| Cut thread | М8 – М30 |

| Automatic tool change | VTS 5/40 3 х 5 positions |

| Marking | 1 x 36 |

| Machine marking by impact (Latin letters + Arabic numerals) with a font height | 10 mm |

Certificates