Reinforcement products prefabrication

Fabrication of reinforcement welded mesh on a special high-performance equipment from cold-formed reinforcement in rolls according to EN 10080 requirements.

| Mesh length (L) | 2500 – 6000 |

| Mesh width (B) | 1500 – 2400 |

| Longitudinal rods diameter | 4 – 12 mm |

| Transversal rods diameter | 4 – 12 mm |

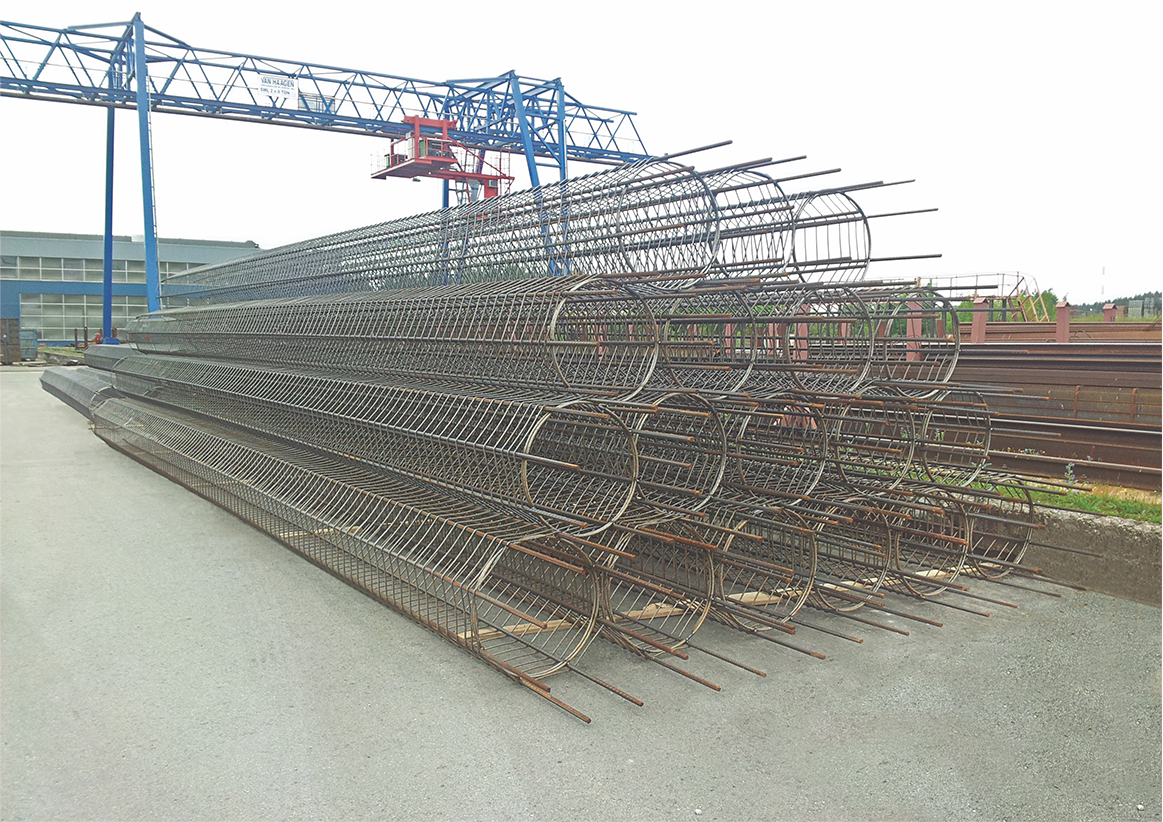

Fabrication of reinforcement cages of round, square and rectangular section on the automatic high-performance equipment using RESISTANCE WELDING method according to the ЕN ISO 14554-2 requirements.

| Cage length | 1500 – 12000 mm |

| Cage diameter | Ø 180 – 1400 mm |

| Distance between spirals | 30 – 200 mm |

| Longitudinal rods diameter | Ø 12 – 36 mm |

| Spiral rods diameter | Ø 6 – 12 mm |

Fabrication of reinforcement cages of round section on the special equipment in carbon dioxide environment using SEMIAUTOMATIC WELDING method according to the EN ISO 17660-1; EN 10080 requirements.

| Cage length | 1500 – 12000 mm |

| Cage diameter | Ø 200 – 500 mm |

| With longitudinal rods diameter | Ø 12 – Ø 22 mm |

| Cage diameter | Ø 600 – 1100 mm |

| With longitudinal rods diameter | Ø 12 – 32 mm |

| Distance between spirals | 50 – 300 mm |

| Longitudinal rods diameter | Ø 12 – 36 mm |

| Spiral rods diameter | Ø 6 – 16 mm |

Fabrication of reinforcement cages of different configurations and complexity at the specialized production sector, applying modern welding equipment and universal assembly tooling, with MANUAL ASSEMBLY method AND WELDING.

The service centre fabricates the rolled cold-formed riffled re-bars of the own making with diameters from 5 mm to 12 mm on the special high-performance equipment.

Smooth rolled wire is used as a source material.

Cold-formed reinforcing bars are supplied in rolls weighing P= +/- 2.5 t for all diameters- Ø 5; Ø 6; Ø 8; Ø 10; Ø 12 mm to customers order.

Fabricated rolls weight – 2500 kg

Fabricated rolls dimensions: outer Ø– 1050 mm/ inner Ø – 630 mm / H height– 850 mm

COLD –FORMED WIRE IN ROLLS MADE BY ELME METALL SERVICE CENTRE

Steel grades: B500A; B500A-SF55; NK500AB-W; B500NA Material standard: EN 10080:2006; SFS1300:2014; SS212540:2014; NS 3576-4:2006; own making wire code: 6 / 1 / 6 (unique, according to EN 10080:2006)

Modern high-performance equipment enables to offer to the customers a various types of processing of reinforcing bars: cutting to size and fabrication of bended parts from smooth wire, as well as from cold-formed and hot-rolled re-bars.

Cutting to size

| From reinforcement in rolls | From straight reinforcement | |

| Automatic correction and cutting | Ø 4 – 16 mm | Ø 8 – 40 mm |

| Length of blanks | 500 – 7000 mm | 500 – 14000 mm |

| Cutting tolerance | +/- 20 mm | +/- 20 mm |

Fabrication of bended parts from reinforcement in rolls.

| Diameters of reinforcement in rolls | Ø 6 – 16 mm |

| Bending angle | +/- 200 |

| Possible min. dimensions of parts in 2D format | 50 mm х 50 mm ( Ø 6 mm) – макс. 1500 mm х 1500 mm |

| Possible bending of part in 3D format | 0 – 90 |

| Approximate radii of replaceable nozzles | 12 mm, 16 mm, 20 mm, 25 mm, 28 mm, 30 mm, 32 mm, 40 mm |

Fabrication of bended parts from straight reinforcement.

| Diameters of straight reinforcement | Ø 8 – 40 mm |

| Part sweep min. length | 500 mm |

| Bending angle | 180 |

| Bending radius | min. 200 mm |

| Approximate radii of replaceable nozzles | 30 mm, 34 mm, 36 mm, 40 mm, 50 mm, 60 mm, 70 mm, 80 mm,100 mm, 120 mm, 150 mm, 190 mm |

Service center lab, fitted out with a modern equipment, with a calibration certificate issued by ICS (Sweden), enables to test the fabricated products according to the EN ISO 15630-1:2010 and EN ISO 15630-2:2010 requirements.