Flat products prefabrication

Plasma cutting

| Min/max thickness | 3 – 50 mm |

| Operating area | 3500 х 22000 mm |

| Plasma cutting and product marking | HPR400XD |

| Tolerances (by default) | ISO 9013 – 432 |

| Crane lifting capacity | 20 t |

| Materials | stainless steel carbon steel |

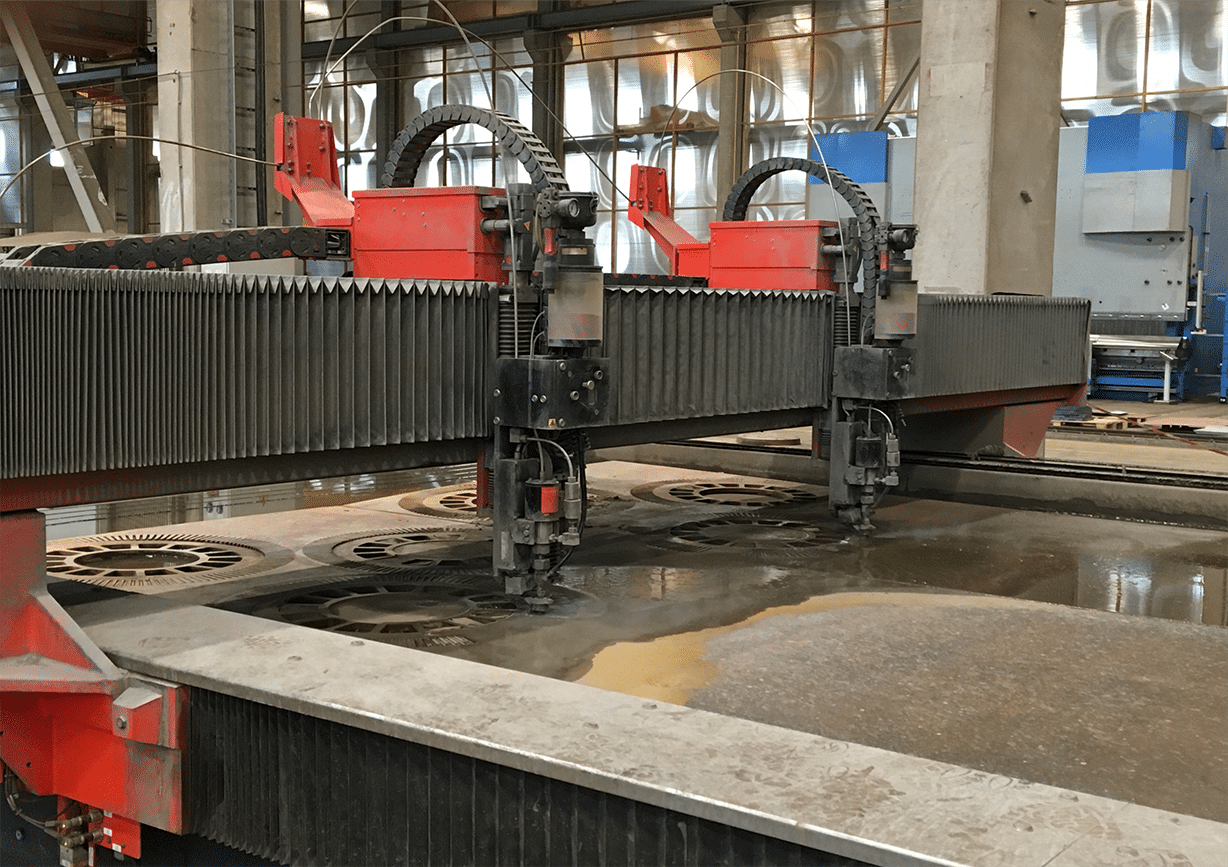

Oxyfuel gas cutting

| Min/max thickness | 15 – 200 mm |

| Operating area | 3600 х 34000 mm |

| 2 portals with 3 cutters | |

| Tolerances (by default) | ISO 9013 – 432 |

| Crane lifting capacity | 20 t |

| Materials | carbon steel |

Beveling with plasma cutting

| Min/max thickness | 3 – 50 mm |

| Cutting area with 2-D straight cut | 3800 х 23000 mm |

| Cutting area with 3-D beveling | 3500 х 22000 mm |

| Plasma cutting and product marking | HPR400XD |

| Bevel angle | 0 – 45 |

| Tolerances (by default) | ISO 9013 – 432 |

| Crane lifting capacity | 12.5 t |

| Materials | stainless steel carbon steel |

Water jet cutting

| Min/max thickness | 3 – 200 mm | |

| Operating area | 3000 х 8000 mm | |

| Cutterheads | 2 straight cuts | |

| КМТ pump | 5200 bar | |

| Tolerances | ISO 9013 – 231 ISO 9013 – 241 ISO 9013 – 2*1 |

3 – 40 mm 40 – 50 mm 50 – 200 mm |

| Crane lifting capacity | 12.5 t | |

| Materials | aluminium alloys stainless steel carbon steel |

Beveling with water jet cutting

| Min/max thickness | 3 – 170 mm | |

| Cutting area with 2-D straight cut | 3000 х 6400 mm | |

| Cutting area with 3-D beveling | 2220 х 5830 mm | |

| Cutterheads | 1-а one for straight cut 1-а one rotator for bevels |

|

| Bevel angle | 0 – 60 | |

| 2 x КМТ pump | 4136 bar | |

| Tolerances | ISO 9013 – 231 ISO 9013 – 241 ISO 9013 – 2*1 |

3 – 40 mm 40 – 50 mm 50 – 170 mm |

| Crane lifting capacity | 12.5 t | |

| Materials | aluminium alloys stainless steel carbon steel |

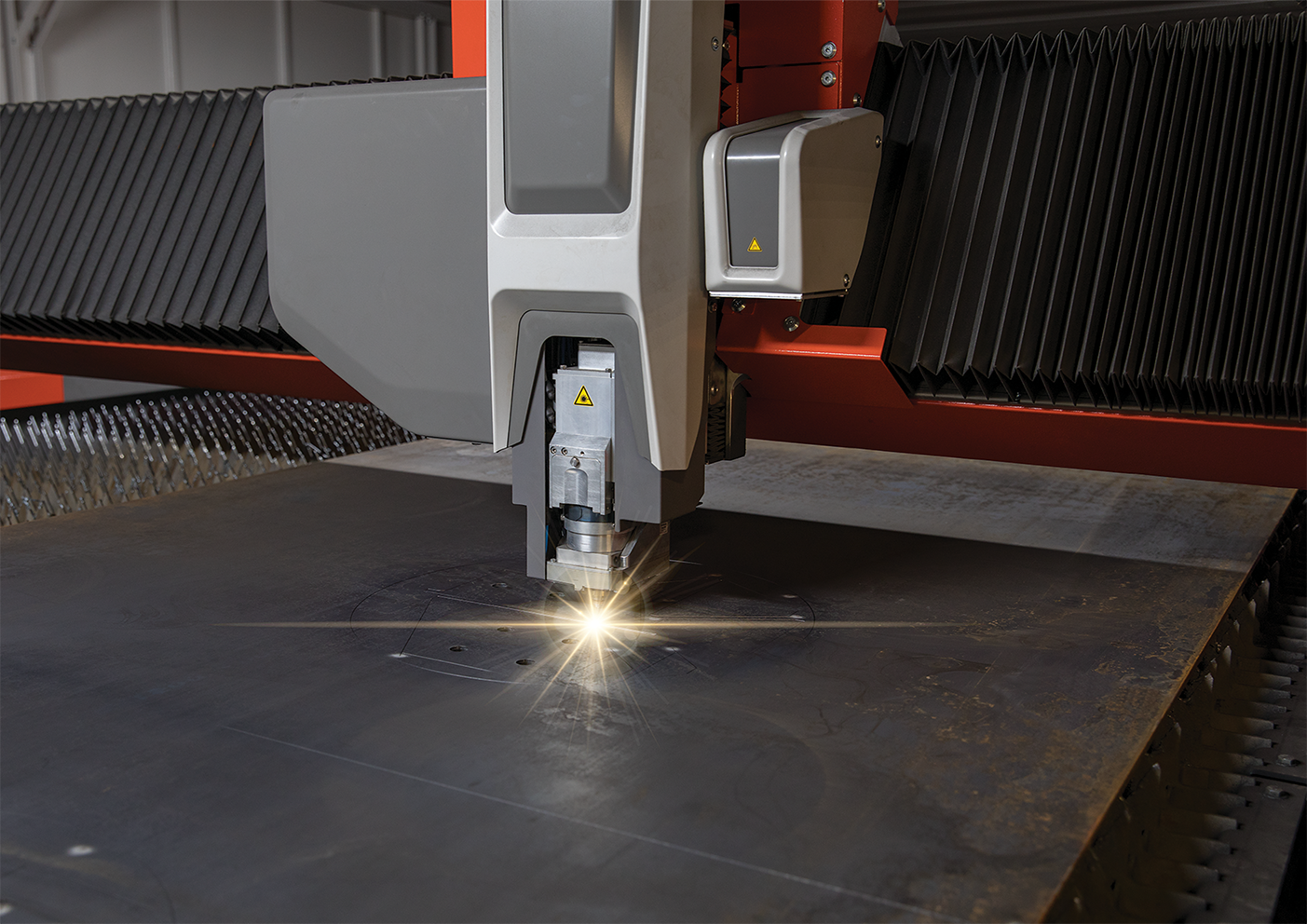

Laser cutting

| Min/max thickness | carbon steel | 0.5 x 25 mm / 0.5 х 30 mm |

| stainless steel | 0.5 x 25 mm / 0.5 х 30 mm | |

| aluminium alloys | 0.5 x 15 mm / 0.5 х 25 mm | |

| Operating area | 2500 x 8000 mm / 2550 х 6250 mm | |

| Plates processing area | 2 | |

| Laser power | 6000 W / 10000 W | |

| Tolerances | ISO 9013 – 221 ISO 9013 – 331 |

up to 15 mm from 15 mm |

| Crane lifting capacity | 5 t |

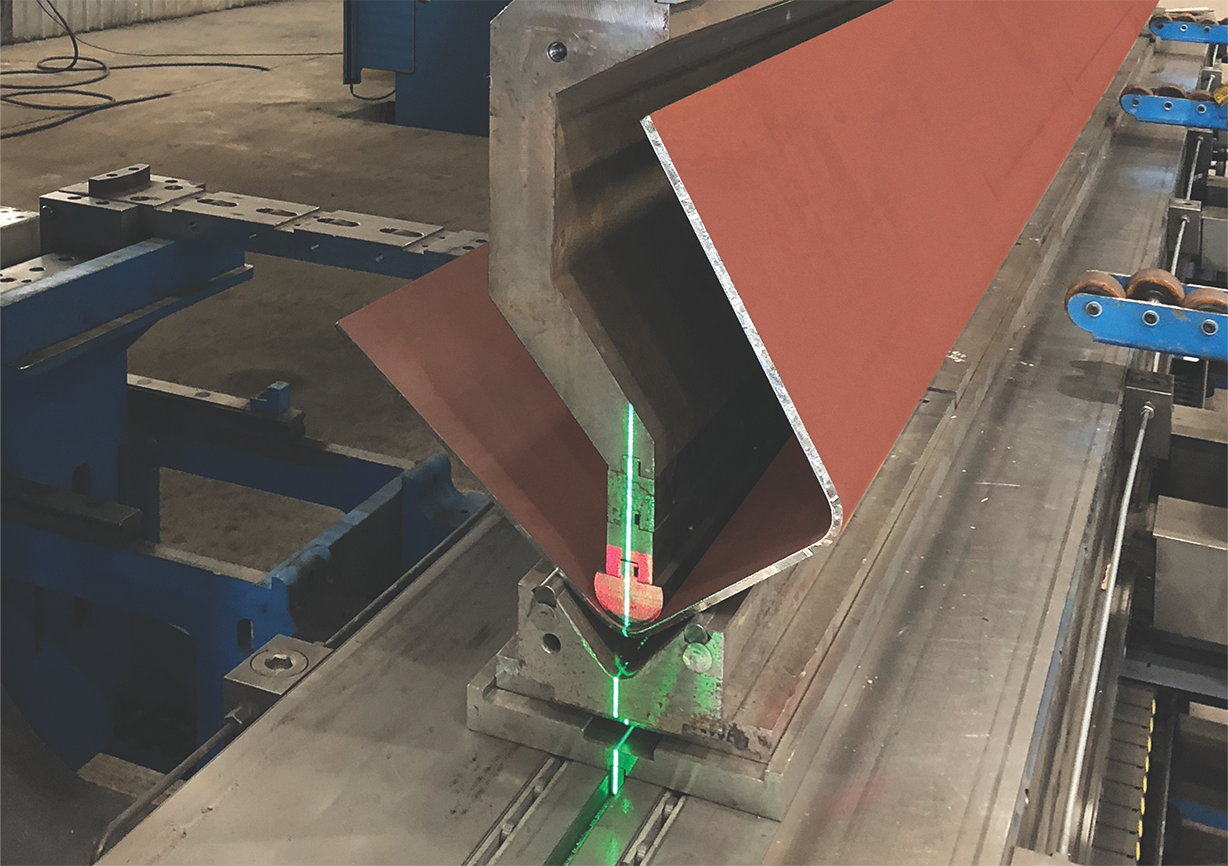

Sheet bending

| Min/max thickness | 1 – 50 mm |

| Workpiece weight | 3600 кг |

| Press power | 400 t 630 t 1250 t |

| Bend angle | 35 – 179 |

| Bend max. length | 7200 mm |

| Product types | angles, ducts, U-channels, cones, Z-profiles etc. |

| Crane lifting capacity | 12.5 t |

| Materials | aluminium alloys stainless steel carbon steel |

Sheet rolling

| Min/Max thickness | 7 – 50 mm |

| Max length | 30000 mm |

| Max length of primed sheet | 18000 mm |

| Min/Mаx width | 800 – 3950 mm |

| Rolls count | 4 |

| Rolls width | 4000 mm |

| Rolls diameter | 540 mm |

| Max diameter | 5000 mm |

| Min diameter | 760 mm |

| Crane lifting capacity | 30 t – 1 crane 5 t – 2 cranes |

| Material | Carbon steel |

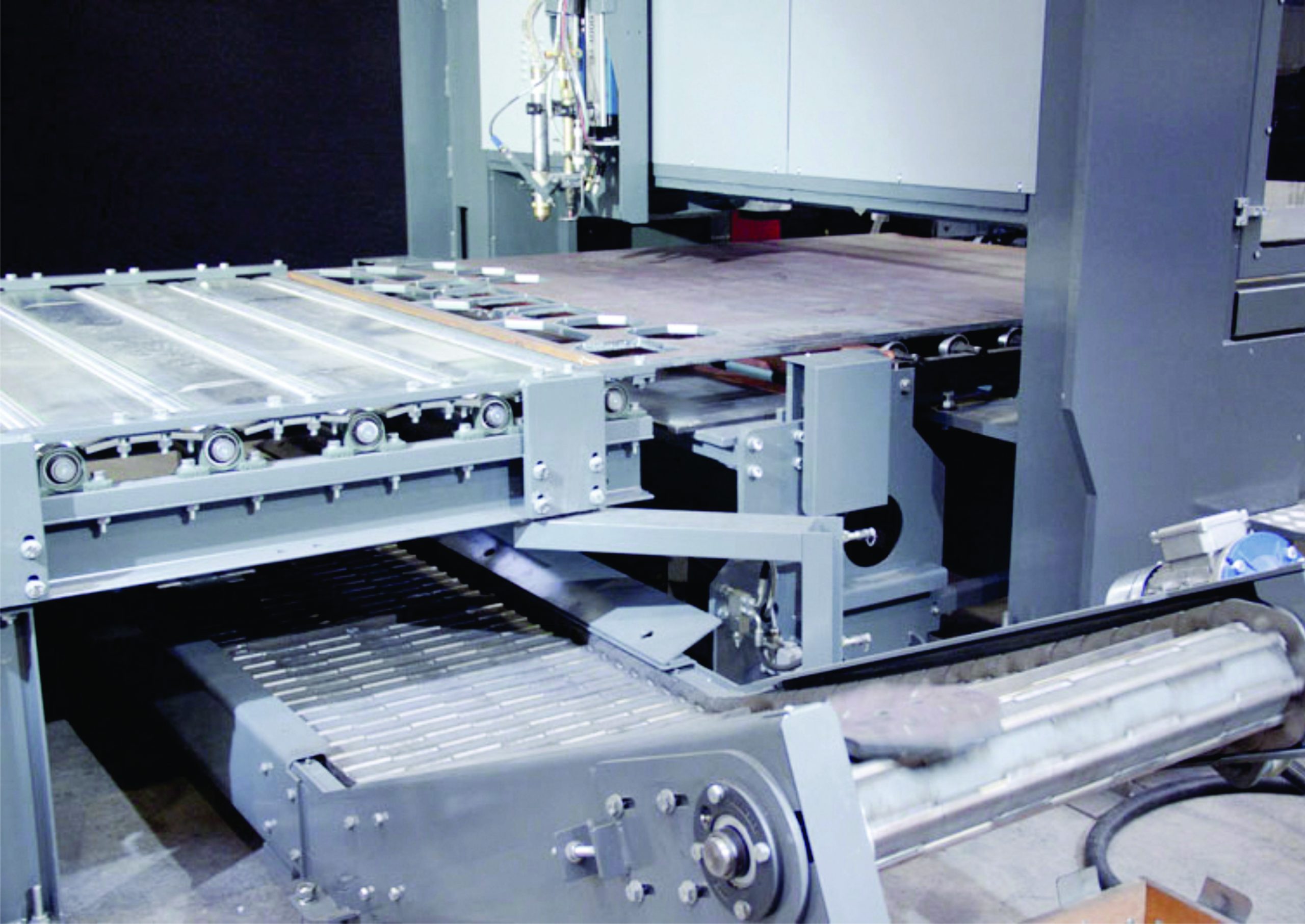

Blank manufacture including drilling holes and threading

| Min./max. workpiece length | 850 – 6100 mm |

| Min/max. workpiece width | 200 – 3050 mm |

| Min/max. workpiece thickness | 6 – 75 mm |

| Min/max. workpiece weight | 9000 kg |

| Cutting | oxyfuel gas or plasma |

| Plasma source | HPR260XD |

| Cutting torch | 1 |

| Plasma cutting | yes |

| Orifice diameter | 80 – 40 mm |

| Cut thread | M8 – M30 |

| Automatic tool change | 10 positions |